TECHNOLOGY

“Emulsification and Dispersion” as Core Technologies Challenge to High Value-Added Technologies

Chukyo Yushi’s original emulsification and dispersion technologies have infinite possibilities. We have responded to needs such as “making what was thought impossible ITEMS with water possible with water” and “cost reduction by making expensive materials into thin films through micronization.” In recent years, these technologies have also been utilized to meet the needs for reducing environmental impact and water-based materials in a circular economy.

PROPRIETARY TECHNOLOGY

01

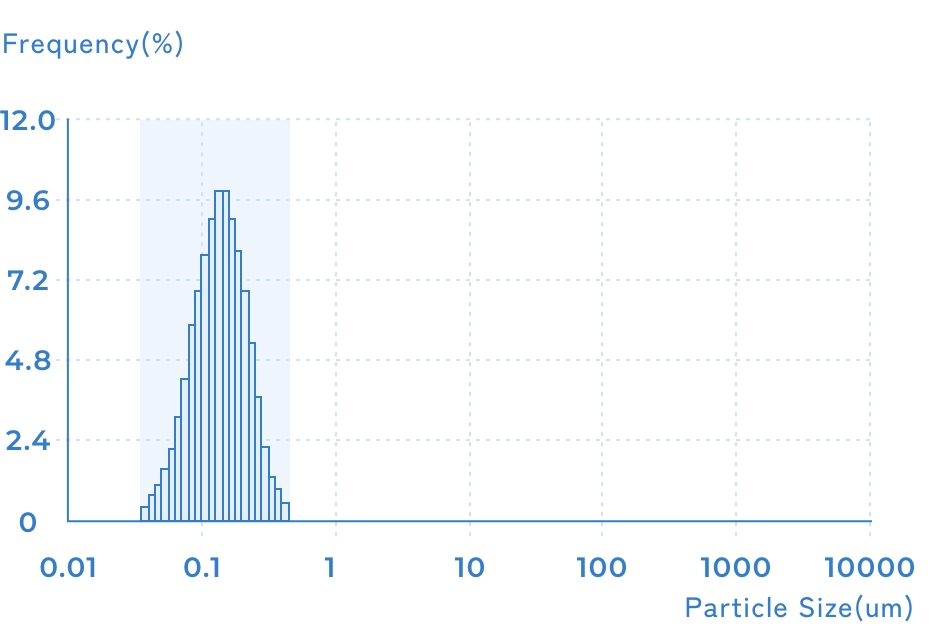

Uniform Particle Size with Sharp Particle Distribution

A sharp particle size distribution indicates uniform material properties, playing a crucial role in maximizing the material’s characteristics and functionality.

Our emulsification and dispersion technology is utilized across various industries to tailor particle sizes to meet diverse needs.

Evaluation Technology

02

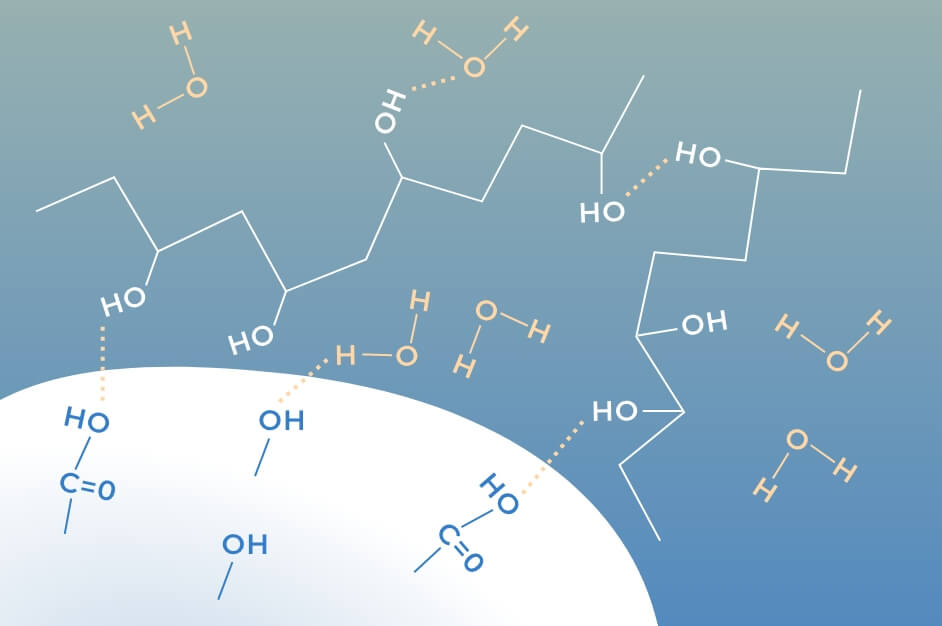

Emulsification and Dispersion Technology for Hydrophilic Substances

The application of surfactants enables the emulsification and dispersion of substances with hydrophilic groups, such as stearic acid (fatty acids), fatty acid amides, and metallic soaps.

By utilizing unique formulation techniques and surfactants, we achieve this by acting on the interface between hydrophilic substances and water.

Evaluation Technology

03

Emulsified and Dispersed Products Resistant to Freezing and Alcohol Mixing

Our unique formulation and dispersion techniques protect emulsified substances against freezing and the addition of alcohol, which can easily disrupt emulsified and dispersed states.

This allows for use under harsh freezing conditions or leverages the excellent wetting and drying properties of alcohol.

Evaluation Technology

04

Emulsification and Dispersion Technology for High Melting Point, High Viscosity Substances

Our unique emulsification, dispersion, and formulation techniques ensure stable emulsification and dispersion of substances that are difficult to disperse in water, such as high-melting-point materials like polyethylene wax (over 100°C) and high-viscosity substances like polybutene.

Evaluation Technology

05

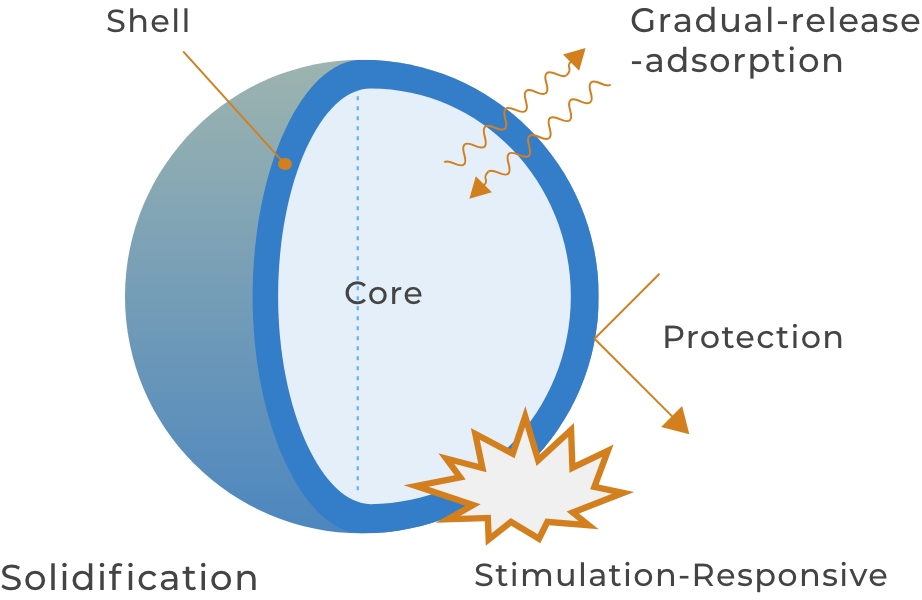

Microcapsules

By conducting polymerization reactions at the interface generated by our core emulsification and dispersion technologies, we can prepare submicron-sized core-shell microcapsules. Depending on the shell design, it is possible to impart properties such as protection, controlled release, and stimulus responsiveness to the core substance.

Evaluation Technology

06

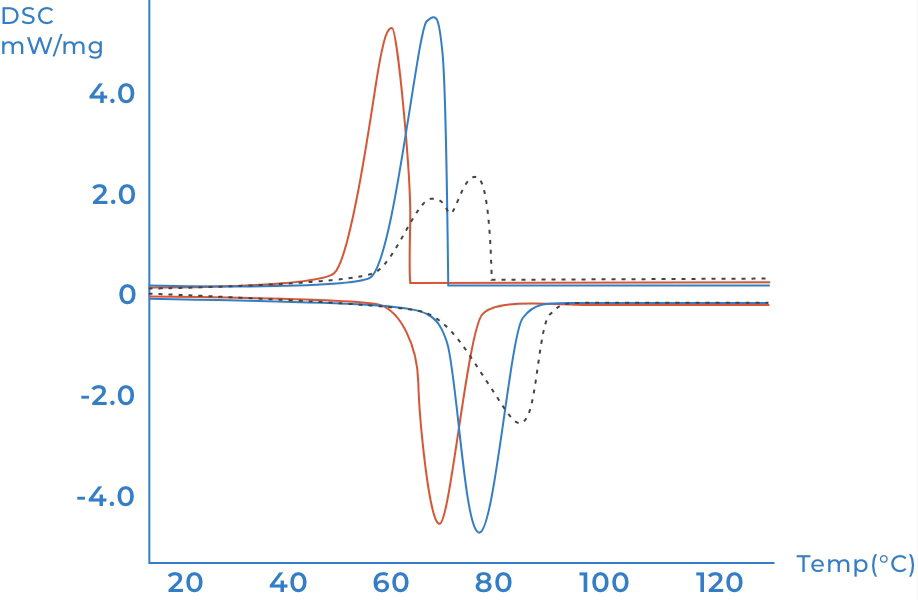

Synthetic Wax

We can synthesize ester waxes through reactions between fatty acids and various alcohols. Ester waxes made from plant-derived raw materials are 100% biomass-based, environmentally friendly materials characterized by sharp melting properties. Additionally, by introducing polar groups into paraffin and α-olefins, we also synthesize oxidized waxes used as dispersants and modifiers in resins, inks, and hot melt adhesives.

Evaluation Technology

EVALUATION TECHNOLOGY

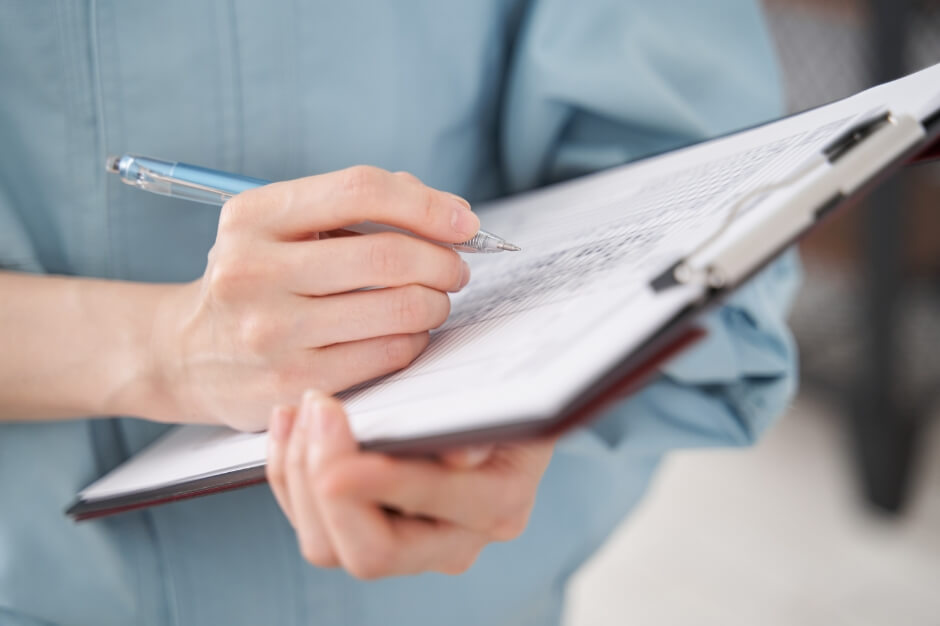

Checking Product Quality According to Customer Evaluation Standards

We believe it is important not only to meet our evaluation standards but also to meet the conditions in our customers’ environments. We check product quality in a state as close as possible to the customer’s environment, aligning evaluation standards as much as possible.

High-Precision Evaluation Technology with Extensive Knowledge in Various Industries

Since our founding, we have supported the manufacturing processes of customers across a wide range of industries, including automotive, coatings, pharmaceuticals, food, and cosmetics, accumulating extensive know-how and expertise.

Our experience is reflected in our ability to provide high-precision evaluations that meet the critical standards valued in each industry.

FACTORY AND EQUIPMENT

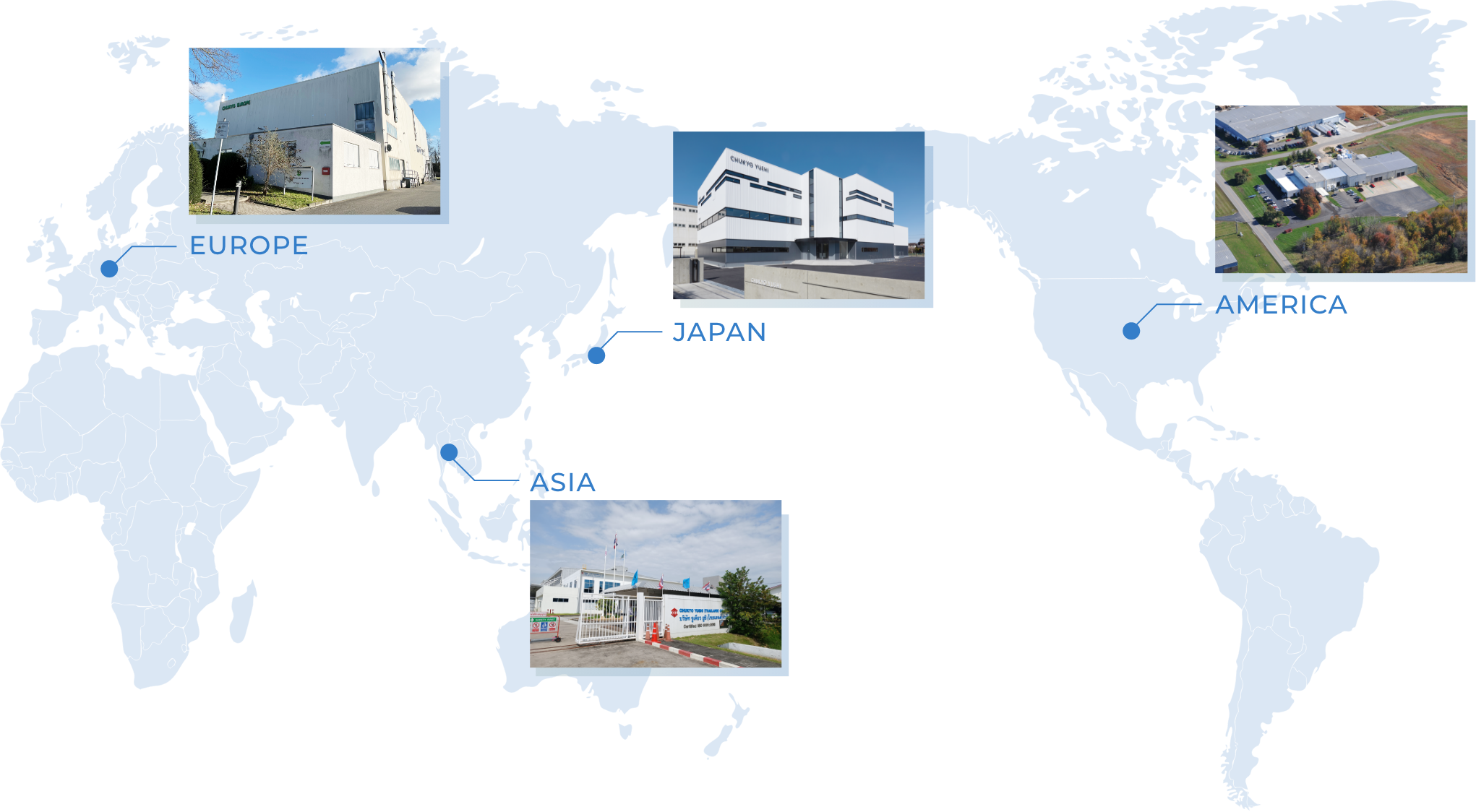

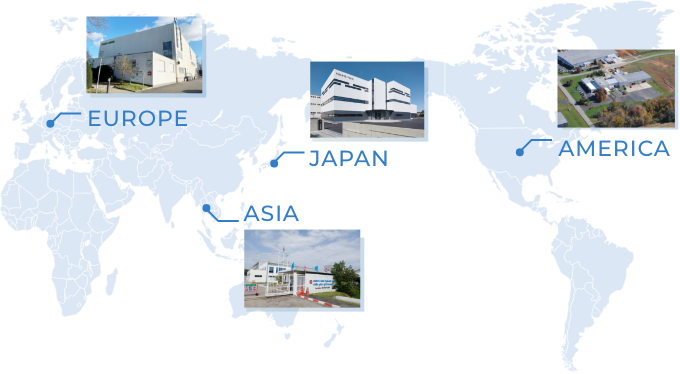

A production system capable of handling a wide variety of products

We have established a system to stably supply the same high-quality products across all locations.

Similarly, we have built a technical service framework at all sites to swiftly respond to new customer demands.

Achieving Stable Supply with a Four-Pole System of

Domestic and Overseas Factories

QUALITY CONTROL

ISO 9001 Certified

We promise to provide products that customers can use with confidence under international quality management standards.

ISO 14001 Certified

We prioritize our responsibility to the environment, promoting conservation efforts and continuous improvement.